Forms and Templates

Downloads for A3 problem solving, standard work, project management, and value stream mapping.

Lean Events and Training / Forms and Templates

Downloads for A3 problem solving, standard work, project management, and value stream mapping.

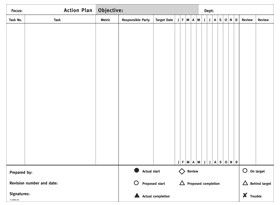

A3 Action Plan Form (from Getting the Right Things Done)

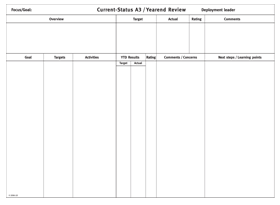

A3 Status Review Form (from Getting the Right Things Done)

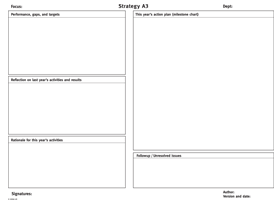

A3 Strategy Form (from Getting the Right Things Done)

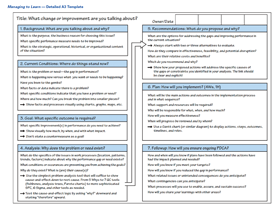

Detailed A3 Template (from Managing to Learn)

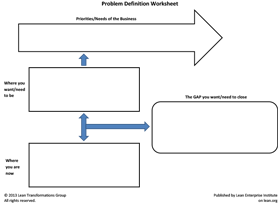

Problem Definition Worksheet

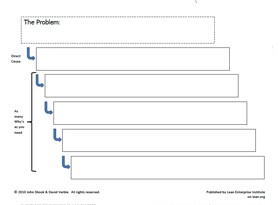

Root Cause Template

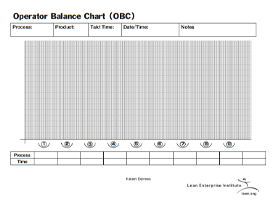

Standard Work Operator Balance Chart (OBC)

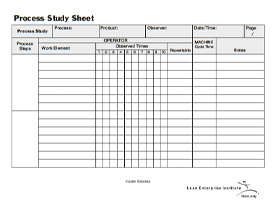

Standard Work Process Study Sheet

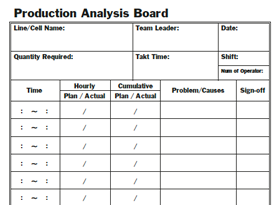

Standard Work Production Analysis Board

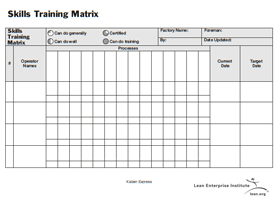

Standard Work Skills Training Matrix

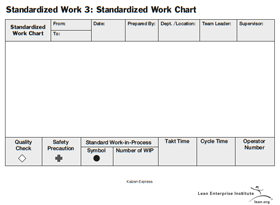

Standardized Work Chart

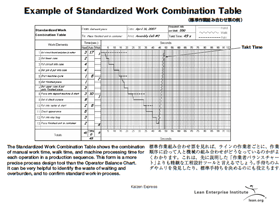

Standardized Work Combination Table

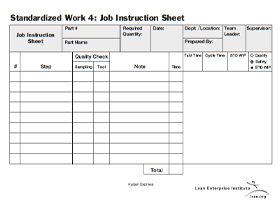

Standardized Work Job Instruction Sheet

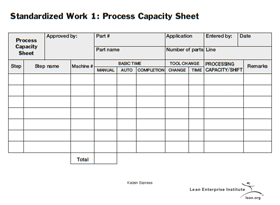

Standardized Work Process Capacity Sheet

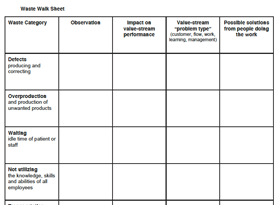

Waste Walk Template (from Perfecting Patient Journeys)

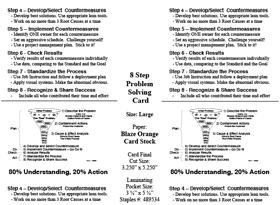

8-step TWI problem solving card - as presented by IBM

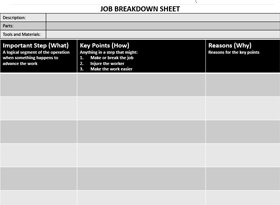

Template of Job Breakdown Sheet

Lean Enterprise Institute

James (Jim) Womack, PhD and Dan Jones

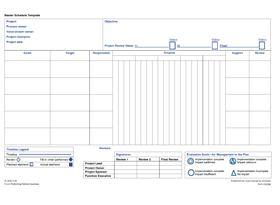

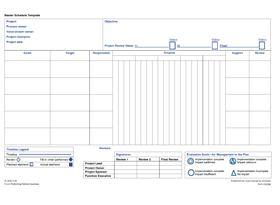

Master Schedule and Action Plan Template for One Goal (from Perfecting Patient Journeys)

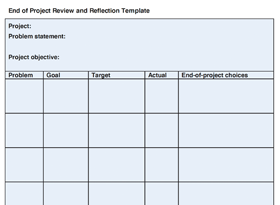

End of Project Review Template (from Perfecting Patient Journeys)

Master Schedule Template (from Perfecting Patient Journeys)

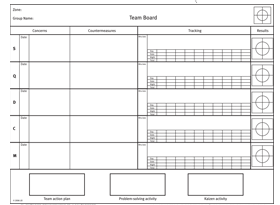

Team Board Form (from Getting the Right Things Done)

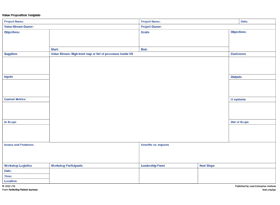

Value Proposition Template (from Perfecting Patient Journeys)

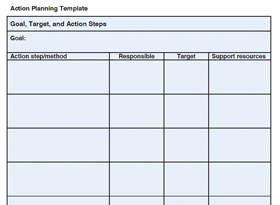

Action Planning Template (from Perfecting Patient Journeys)

Beau Keyte, Tom Shuker and Judy Worth

Pascal Dennis

Value-stream Mapping Icons for Excel

Mike Rother and John Shook

Lean Enterprise Institute, Mike Rother and John Shook

Mapping to See: Value-Stream Improvement Workshop

Beau Keyte, Jim Luckman, Kirk Paluska, Guy Parsons, John Shook, Tom Shuker and David Verble